This guideline collates all of the leading laser makes in one area, describing what each corporation does nicely as well as regions they specialize in. We’ll also select 1 of every manufacturer’s best products to give you an notion of what to count on.

com, advertising in listing Publications and Internet sites, and networking with dealers across the country, we have the skills to get you quite possibly the most money for the metal working machines, in the the very least period of time.

Melt and blow or fusion slicing utilizes high-pressure fuel to blow molten product from the chopping location, tremendously decreasing the ability requirement.

After you think about the size of this system, you can certainly decide that it shouldn’t be positioned in the most beneficial laser engraver reviews. But listed here it is getting the top desktop laser engraver as well as a cutter with its surprisingly lower cost and in many cases smaller footprint.

CNC routers are Yet another variety of Laptop or computer managed machine. Like waterjets and laser cutters, they've got a slicing head that travels over a gantry and is particularly used to chop the fabric.

The notches are patterned along the region where you wish your content to bend, which loosens up the material enough to allow it to flex quite nicely. Other layout tactics is often used to make use of the flexibleness as well, to generate snap fit hinges that hold the parts locked together.

In case you are keen on Discovering more details on 3D printing, look into this Instructable for an introduction.

You may also create PAUSE in the midst of your method and jog Each and every axis independently although your application is in pause mode.

A CNC metal milling machine is a pc-controlled machine tool for shaping and cutting metal products with high precision. It works by making use of CNC(Computer system Numerical Control) technology that instructs the actions by way of a preprogrammed set of commands.

Mazak turning centers are created with many Highly developed attributes that substantially boost machining capabilities:

Used CNC vertical machining centers have a vertically oriented spindle, enabling tools to stick straight down and Minimize across the top of a bit of material.

The key drawback of laser chopping will be the high electricity intake. Industrial laser performance may range from 5% to 45%.[19] The power consumption and efficiency of any distinct laser will range depending on output energy and check here operating parameters. This will likely rely upon the kind of laser And the way nicely the laser is matched into the function at hand.

You'll be dissatisfied from the screw within the Z generate—the amount of Engage in that screws have had within the moving nut whilst becoming threaded.

As soon as the steppers have deactivated, you are able to migrate the gantry from the hand. In addition it will save a lot of time.

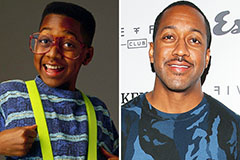

Jaleel White Then & Now!

Jaleel White Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Traci Lords Then & Now!

Traci Lords Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!